Banding Automation for Offset Printers

Feeder - Stacker - Bander - FSB

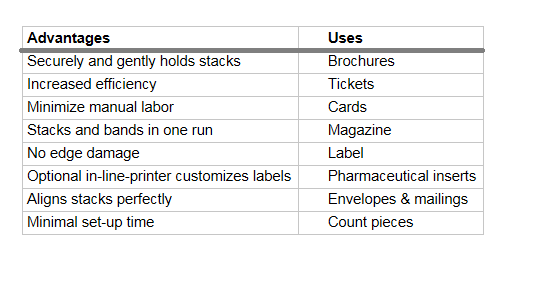

Commercial sheet-fed and offset printers and converters worry about price reduction pressures, lead-times, and closely monitor raw material usage. Any of our banding machines help with these three main concerns in the industry.

Banding can replace strapping or shrink wrapping of cut pieces and yet protect the finished printed piece with a gentle band. These automation machines help companies use less labor, and banding uses less raw materials, so it is economical and environmentally friendly.

The ATS-FSB - automated feeder and stacker is usually placed after folding machines or saddle stitchers or behind the guillotine cutter for maximum efficiency. The machine counts, squares and bands printed products with no damage to edges or corners.

Don't need a stacker-bander? We have other forms of automatic banding machines.In fact, we can desgin a sytem to specifically fit into your process. Check out our other automation pages, or fill out the form on the right to get more information about banding automation.

Banding Automation │ Banding Automation for Narrow Web (Labels) │ Corner Line Automatic Banding Machine

Want help identifying the sustainable packaging solution that is best for you?